TOF 3D Inspection: Boosting Accuracy and Precision in Industrial QC

How can TOF 3D inspection improve quality control efficiency on industrial production lines?

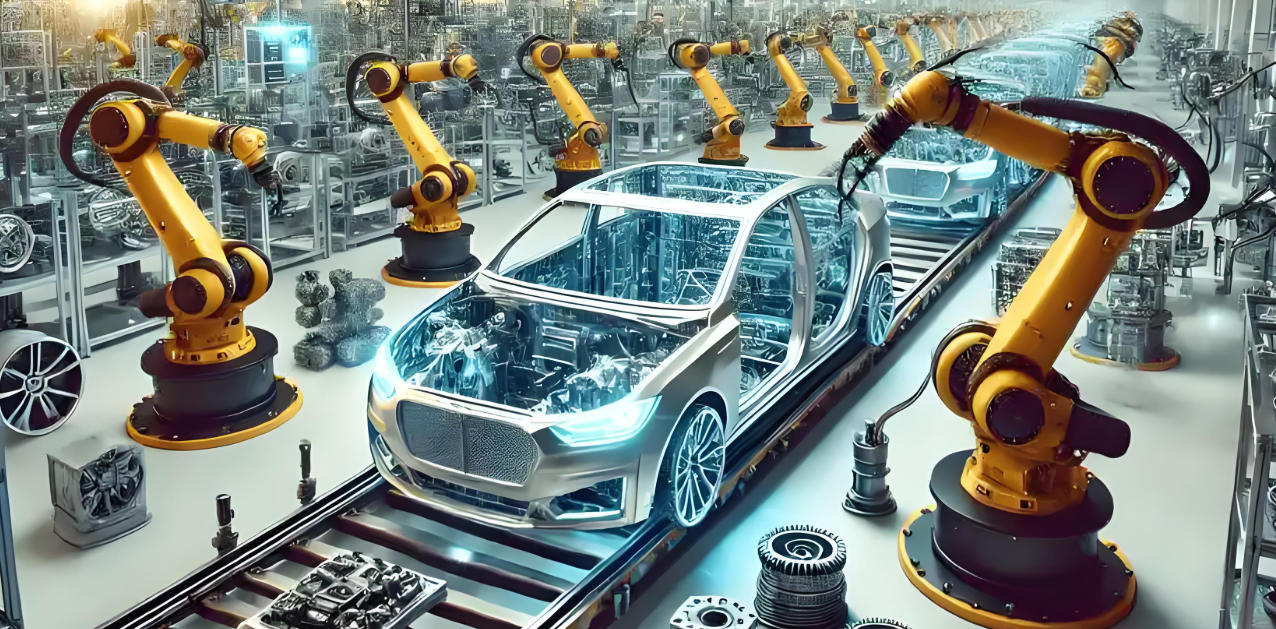

In today’s rapidly advancing industrial automation, quality control has become a core competitiveness of manufacturing enterprises. Traditional inspection methods, limited by manual labor and 2D vision, often struggle to ensure measurement and precision. With the development of TOF (Time-of-Flight) (https://en.wikipedia.org) inspection and the 3D depth camera, industrial quality inspection is entering a new era.

As an advanced camera for 3D inspection, TOF not only enables efficient defect detection but also addresses the issue of accuracy vs precision, making quality inspection more scientific and reliable. This article explores the advantages of TOF inspection in industrial 3D quality control, application cases, comparisons with other measurement technologies, and explains the difference between accuracy and precision.

What is a 3D Depth Camera?

A 3D depth camera is a sensor capable of capturing three-dimensional spatial information of objects. Unlike ordinary 2D cameras, it not only records color and texture but also measures the distance from each pixel to the camera, generating a 3D depth map or point cloud data of the object or scene.

Working Principle

Common 3D depth camera technologies include:

-

TOF (Time-of-Flight): Emits infrared or laser pulses, measures the time taken for the light to return, and calculates the distance to the object.

-

Structured Light: Projects specific grids or patterns onto the object’s surface, and calculates the 3D shape from the deformation of the pattern.

-

Stereo Vision: Uses two or more cameras to calculate depth information from disparity, similar to how human eyes perceive distance.

Simply put, a 3D depth camera allows devices to 'see' the shape and spatial position of objects, providing precise 3D perception for industry, smart devices, and interactive applications.

1. Current Challenges in Industrial Quality Control

Although industrial automation continues to advance, traditional inspection methods still face significant limitations and fail to fully meet the demands of modern high-precision production. The main issues are:

-

Human Error

Many enterprises still rely on manual inspection, which depends heavily on worker experience and subjective judgment. When tasks are repetitive and long, fatigue leads to inconsistent standards. This makes it hard to guarantee accuracy or precision, and results may vary across workers for the same batch of products.

Example of accuracy vs precision: In electronics manufacturing, workers may correctly identify defective solder joints (accuracy), but their varying judgment standards for minor defects cause poor precision, affecting product consistency and yield. -

Low Efficiency

In high-throughput production, such as automotive parts machining or smartphone assembly, manual inspection cannot keep up with speed. Once inspection becomes a bottleneck, it slows down the production line, and undetected defects may flow into later processes, raising rework and maintenance costs. -

2D Limitations

Traditional 2D cameras capture only surface texture and color, making them ineffective for detecting 3D features like dents, bumps, or gaps. This means dimensional deviations and geometric errors are often overlooked, reducing the precision of measurement. For example, a 2D system may fail to detect slight misalignment of car part holes, which directly affects assembly precision and safety.

These pain points show that traditional inspection cannot meet the high standards of modern manufacturing. The industry urgently needs 3D inspection technology, especially solutions that balance accuracy and precision on production lines. Such technologies not only eliminate human inconsistency but also achieve high speed and reliability in automated quality control.

2. How TOF Enables High-Precision 3D Inspection

TOF inspection is a measurement technology that calculates distance using the flight time of light. By emitting infrared pulses and measuring the return time, it captures the 3D depth of surfaces and generates high-precision point cloud data. Unlike 2D imaging, TOF provides complete 3D spatial coordinates, offering more comprehensive data support for quality control.

Key advantages of TOF 3D depth cameras in industrial inspection:

-

Surface Defect Detection

TOF cameras can quickly detect scratches, dents, and burrs, reducing missed defects common in manual inspection. This improves both accuracy and precision while reducing scrap and rework rates. -

Dimensional and Geometric Measurement

TOF can measure length, width, height, angles, and more in real-time, comparing them with standard models for precision visualization. For example, in automotive parts manufacturing, TOF can detect bolt hole misalignment or weld spot deviations to ensure assembly safety. -

Real-Time Inspection & Efficiency Optimization

Compared to laser scanning or structured light, TOF has a natural speed advantage. It can operate on high-speed production lines, ensuring both efficiency and accuracy. For large-scale quality control, TOF reduces labor costs while maintaining consistent results. -

Stability & Adaptability

TOF is less sensitive to ambient light interference, making it suitable for diverse industrial environments—whether bright, dim, or dusty—while maintaining reliable measurement precision.

Because of these strengths, TOF is considered one of the most promising measurement technologies in industrial quality control. It provides a solid foundation for accuracy vs precision, shifting inspection from 'post-production defect discovery' to 'real-time prevention,' advancing toward smarter, automated quality control.

3. Industry Application Cases

Electronics Manufacturing

In PCB production, traditional optical inspection often fails to guarantee the measure of accuracy. For instance, slight solder joint misalignments or insufficient solder may go undetected in 2D inspection, raising rework rates.

By introducing TOF inspection, high-resolution 3D point cloud data allows precise evaluation of solder height, position, and pin alignment. This aligns with the definition of accuracy vs precision, while enabling millisecond-level inspection. As a result, TOF improves efficiency, yield, and reliability.

Example: On high-end smartphone PCB assembly lines, TOF 3D depth cameras detect solder height variations in real-time, identifying even micron-level defects. This ensures product reliability and fulfills the dual requirements of accuracy and precision.

Automotive Parts

In automotive manufacturing, assembly precision directly impacts safety and performance. Manual inspection is not only slow but also inconsistent in precision derived from accuracy.

With TOF inspection, parameters like bolt hole positions, weld depths, and assembly gaps are monitored in real time, ensuring compliance with design standards. Even a 0.1 mm misalignment in bolt holes can cause safety risks at high speeds, but TOF point cloud data quickly identifies such deviations, reducing rework and risks.

This clearly illustrates accuracy vs precision in practice:

-

Accuracy: Ensuring components meet design specifications.

-

Precision: Ensuring consistency across every batch of products.

Through these cases, it’s clear that TOF inspection not only balances accuracy and precision, but also drives quality control toward speed, intelligence, and automation. It ensures high yield in electronics and high safety in automotive, while elevating overall industrial quality control.

4. Comparison with Other 3D Inspection Technologies

In industrial quality control, common 3D measurement technologies include laser scanning, structured light, and TOF (Time-of-Flight) cameras. Their performance in terms of accuracy and precision varies, and their suitability differs across scenarios.

-

Laser Scanning

Laser scanning acquires depth information point by point. Its accuracy statistics are usually excellent, capable of achieving micron-level measurement accuracy.

However, this method faces obvious bottlenecks in high-speed production lines: due to limited scanning speed, it struggles with large-scale, real-time inspection. Additionally, laser scanning equipment is costly and complex to maintain, making it difficult to adopt in mass production. -

Structured Light

Structured light projects specific grids or patterns onto the target and calculates depth from the captured deformation. In controlled laboratory environments, structured light can achieve high accuracy. However, in industrial conditions, it faces challenges.

Highly sensitive to ambient light, structured light performs inconsistently under strong light, reflective surfaces, or complex textures, making its accuracy equation unstable. Moreover, processing structured light data requires significant computing resources, affecting real-time performance. -

TOF Inspection

Compared with the above, the TOF 3D depth camera measures the round-trip time of light pulses to obtain depth, combining both speed and stability. It not only meets real-time inspection demands on high-speed lines but also maintains robustness in varied lighting conditions.

More importantly, TOF addresses the accuracy vs precision difference effectively:-

Accuracy: Ensures measurements are close to the true geometric size.

-

Precision: Ensures consistent results across batches in mass production.

-

This makes TOF an ideal solution for balancing accuracy vs precision—ensuring products meet design standards while maintaining stable results across every batch.

Explaining the Difference Between Accuracy and Precision

To understand why TOF is better suited for industrial inspection, we must clarify what are the differences between accuracy and precision:

-

Accuracy: How close a measurement is to the true value.

-

Precision: How consistent repeated measurements are with each other.

Examples:

-

If a device repeatedly measures the diameter of the same hole and all values are very close to each other but deviate from the true size → high precision, low accuracy.

-

If the average result is close to the true size but the measurements vary widely → high accuracy, low precision.

-

TOF, through optimized algorithms and hardware, achieves both: values close to the truth and consistent across measurements, fulfilling the accuracy vs precision definition.

Thus, TOF not only offers better speed and cost efficiency for industrial use but also achieves an ideal balance of accuracy versus precision, making it the core solution for 3D industrial inspection.

5. Future Development Directions

With the continuous evolution of industrial automation and intelligence, TOF inspection will see broader applications in the future. Its progress lies not only in hardware improvements but also in deeper integration with other technologies and intelligent applications. Key trends include:

-

Multi-Sensor Fusion

Future inspection systems will combine TOF cameras with RGB cameras, infrared sensors, and even laser modules, forming a multi-sensor quality control platform.

This allows simultaneous capture of geometric depth and surface texture, better balancing accuracy vs precision in complex scenarios. For example, in inspecting reflective metal parts, the RGB camera provides texture and color, while TOF delivers high-precision geometry, ensuring complete and robust detection. -

AI-Powered Quality Control

With artificial intelligence and machine learning, inspection will go beyond defect detection to predictive maintenance. AI can perform calculation for accuracy on big data, quickly identifying deviations from standards and predicting potential risks.

Example: AI may detect minor equipment shifts from historical data, warning the line for adjustment before defects occur. This transforms TOF inspection from 'problem detection' to 'problem prevention.' -

Adaptive Inspection

As industrial big data advances, TOF systems will increasingly self-learn and optimize. They will adjust inspection strategies based on product types and batch requirements, applying accuracy vs precision definition dynamically.

Example: On high-speed lines, the system may prioritize speed (slight reduction in precision), while in high-value component inspection, it may prioritize accuracy and completeness. This enables true intelligent, adaptive inspection.

Vision of Intelligent Industrial Quality Control

Future 3D inspection will evolve into a complete intelligent quality management system. Guided by the principle of accuracy vs precision difference, it will continuously improve efficiency and consistency. Through sensor fusion, AI, and adaptive control, inspection will enter an era of predictive, intelligent quality management:

-

From passive 'defect detection' to proactive 'defect prediction.'

-

From simple 'dimension measurement' to comprehensive 'quality evaluation.'

-

From local optimization to 'system-level intelligent control.'

This means TOF inspection will become a core component of industrial measurement technology, supporting smart manufacturing and Industry 4.0 with powerful quality control capabilities.

Conclusion

As a new-generation camera for 3D technology, TOF inspection is reshaping industrial quality control by excelling in accuracy and precision difference.

-

It addresses the shortcomings of traditional inspection in accuracy vs precision with examples.

-

It ensures reliable precision of measurement in complex industrial environments.

-

It drives industrial automation toward higher intelligence and efficiency.

In the future, with AI and IoT integration, the TOF 3D depth camera will become a cornerstone of industrial automation and measurement technology, enabling enterprises to achieve true unification of accuracy versus precision in quality control.

Synexens 3D Of RGBD ToF Depth Sensor_CS30

Our professional technical team specializing in 3D camera ranging is ready to assist you at any time. Whether you encounter any issues with your TOF camera after purchase or need clarification on TOF technology, feel free to contact us anytime. We are committed to providing high-quality technical after-sales service and user experience, ensuring your peace of mind in both shopping and using our products.