Exploration de l'utilisation des capteurs TOF dans l'inspection industrielle et le contrôle qualité

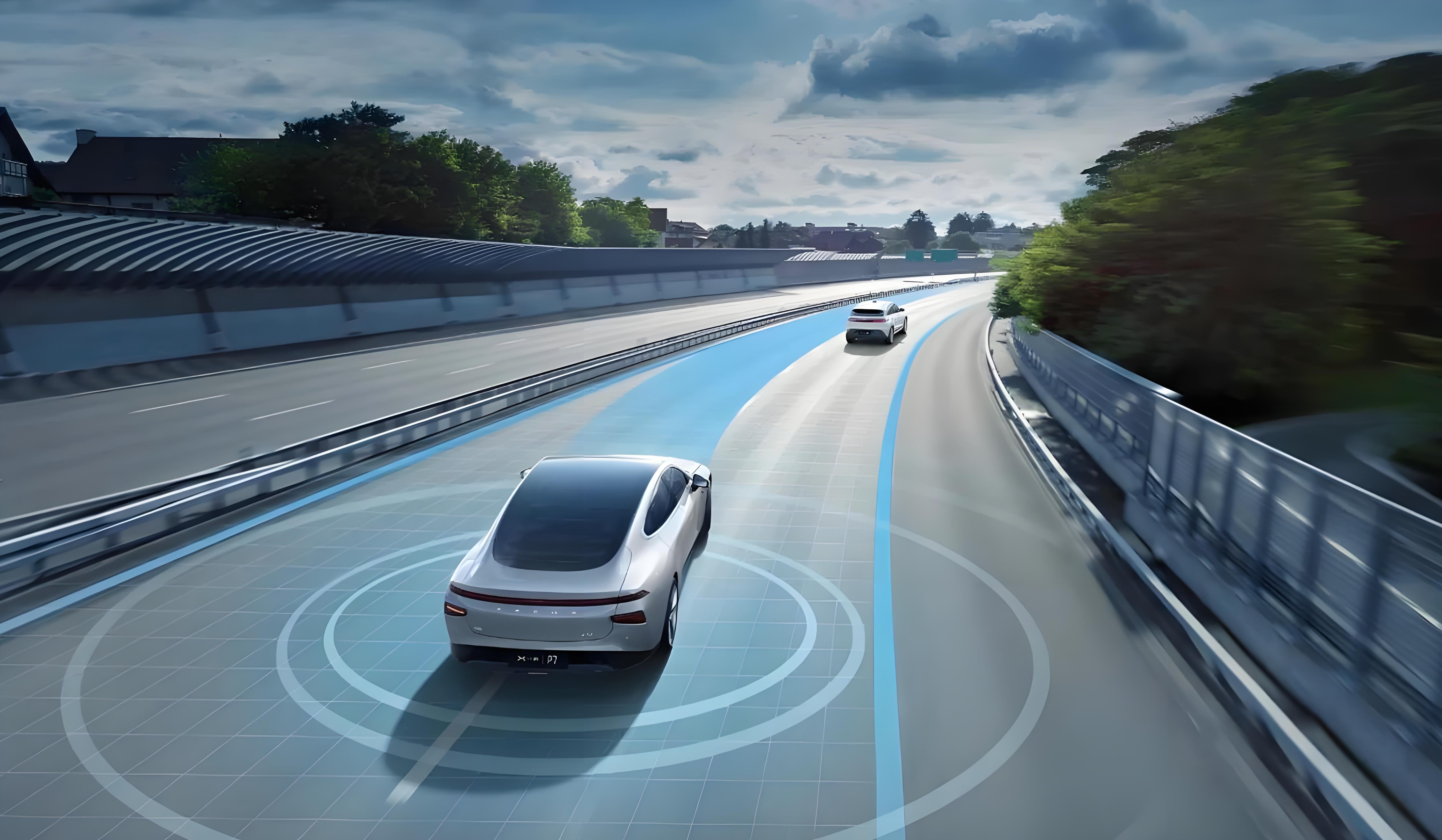

Les capteurs de temps de vol (TOF) sont devenus de plus en plus populaires ces dernières années en raison de leur capacité à mesurer avec précision les distances en temps réel. Bien que ces capteurs aient traditionnellement été utilisés dans des applications telles que la robotique, les véhicules autonomes et les jeux vidéo, ils se sont également révélés inestimables dans le domaine de l'inspection industrielle et du contrôle qualité.

Les capteurs TOF utilisent le principe du temps de vol pour mesurer la distance entre le capteur et un objet. Ils émettent une impulsion lumineuse et mesurent le temps que met la lumière à rebondir sur l'objet, ce qui permet de calculer la distance entre le capteur et l'objet. Cette technologie est particulièrement utile dans l'inspection industrielle et le contrôle qualité, car elle permet de réaliser des mesures sans contact des paramètres critiques tels que la distance, la position et l'orientation des objets.

L'un des principaux avantages des capteurs TOF dans l'inspection industrielle et le contrôle qualité est leur capacité à améliorer la vitesse et la précision des mesures. Les méthodes de mesure traditionnelles, comme la mesure par contact, peuvent être chronophages et nécessiter des équipements spécialisés. Les capteurs TOF, en revanche, fournissent des mesures précises en temps réel, réduisant ainsi le besoin de mesures manuelles et rationalisant le processus d'inspection. Cela peut entraîner une augmentation de la productivité et une réduction des temps d'arrêt, ce qui se traduit par des économies de coûts significatives pour les fabricants.

Un autre avantage des capteurs TOF dans l'inspection industrielle et le contrôle qualité est leur capacité à fonctionner dans des environnements difficiles. De nombreux processus de fabrication se déroulent dans des environnements dangereux pour les opérateurs humains, comme les fours à haute température ou les zones exposées à des produits chimiques nocifs. Les capteurs TOF peuvent fonctionner dans ces environnements sans compromettre la sécurité des opérateurs humains, offrant une solution fiable et précise pour mesurer des paramètres critiques.

Les capteurs TOF peuvent également être utilisés à des fins de contrôle qualité. Dans la fabrication, il est essentiel de garantir que les produits respectent des normes de qualité spécifiques avant d'être livrés aux clients. Les capteurs TOF peuvent mesurer les dimensions, inspecter les surfaces et détecter les défauts en temps réel. Cela permet aux fabricants d'identifier et de résoudre rapidement les problèmes de qualité, en veillant à ce que les produits respectent les spécifications requises avant leur mise sur le marché.

Les capteurs TOF sont également utiles pour garantir la sécurité des processus de fabrication. Par exemple, dans les lignes d'assemblage automatisées, les capteurs TOF peuvent détecter la présence de travailleurs et arrêter les machines pour éviter les accidents. De plus, ils peuvent surveiller la position des pièces mobiles, en s'assurant qu'elles restent dans des limites sécurisées, minimisant ainsi les risques d'accidents.

En conclusion, les capteurs TOF se sont révélés inestimables dans l'inspection industrielle et le contrôle qualité. Leur capacité à fournir des mesures sans contact, à fonctionner dans des environnements difficiles et à améliorer la vitesse et la précision des mesures en font un outil précieux pour les fabricants. À mesure que la technologie continue de progresser, il est probable que nous verrons encore plus d'applications des capteurs TOF dans le domaine de l'inspection industrielle et du contrôle qualité.

Produits applicables : CS20, CS30, CS20-P, CS40, CS40p.

-

Publié dans

Tof sensor