TOF Technology in Infrastructure Inspection: Applications & Advantages

With the acceleration of modern urbanization, the construction and maintenance of infrastructure have become essential components of urban management. Especially for infrastructures such as bridges, tunnels, roads, and buildings, their inspection is directly related to public safety and the sustainable development of cities. Traditional manual inspection methods suffer from inefficiencies, complex working environments, and high risks, making them inadequate to meet the growing demands for infrastructure monitoring. Time of Flight (TOF) technology, as a high-precision depth perception technology, has gradually become an essential tool in infrastructure inspections due to its remarkable advantages.

What is a ToF time of flight sensor?

A TOF (Time of Flight) sensor is a device that calculates the distance between the sensor and the object by measuring the time it takes for a light pulse to travel from the sensor, reflect off the object's surface, and return. The basic principle involves emitting a short light pulse towards the target, which reflects off the object and returns to the sensor. By calculating the time difference between the emission and return of the light pulse, the distance to the object can be determined. This process allows for millimeter-level precision, providing real-time three-dimensional spatial data.

By measuring the return time of reflected light, TOF sensors effectively capture depth information about the target and generate three-dimensional point cloud data, which helps analyze and assess the state of objects. This makes TOF technology especially suitable for infrastructure health monitoring, providing high-precision structural assessments. Due to the fast speed of light, TOF sensors can achieve extremely accurate measurements through time precision.

The advantage of TOF sensors is their ability to generate high-precision three-dimensional depth data, which is not affected by environmental lighting conditions. Therefore, TOF sensors are widely used in autonomous driving, robotics navigation, 3D imaging, agricultural monitoring, and infrastructure inspection.

In infrastructure inspection, TOF sensors can scan the surfaces of structures, capturing even small cracks, settlement, or other structural damages, providing detailed data for subsequent repair and reinforcement work.

Applications of TOF Technology in Infrastructure Inspection

1. Bridge and Tunnel Health Monitoring

Bridges and tunnels, as crucial transportation infrastructures, directly impact traffic flow and public safety. Through TOF technology, the surface shape of bridges or tunnels can be accurately measured to detect cracks, deformations, and settlement. Especially for old bridges or complex tunnel structures, TOF technology can provide more efficient and accurate data than traditional inspection methods. TOF technology also offers real-time scanning and the generation of depth images, providing engineers with detailed three-dimensional structural data to avoid omissions and errors, improving inspection accuracy.

In tunnels, traditional inspection methods are often limited by narrow spaces and poor lighting conditions. TOF technology, through infrared technology, can effectively penetrate low-light environments, ensuring continuous and accurate data collection.

2. Road and Traffic Facility Inspection

Roads are a core part of urban infrastructure, and issues like road wear, cracks, and settlement directly affect traffic safety and the road's operational capacity. TOF technology, with its high-precision depth data, can accurately detect various issues on road surfaces, including cracks, ruts, and settlement. Using TOF sensors, inspection personnel can quickly scan roads without halting operations and generate detailed three-dimensional maps, providing comprehensive technical support for subsequent repair work.

In addition, TOF technology can assist in monitoring traffic facilities such as traffic signs and traffic lights. By real-time collection and analysis of the status of these facilities, TOF technology can effectively reduce the frequency and cost of manual inspections.

3. Building and High-Rise Structure Inspection

TOF technology is also suitable for the health monitoring of buildings and high-rise structures. By performing three-dimensional scans of building facades, TOF sensors can detect cracks, tilting, and settlement issues. This technology does not require direct contact with the building, ensuring the safety and efficiency of the inspection process. Especially for high-rise buildings and those with complex facades, TOF technology can provide comprehensive three-dimensional structural data, helping inspectors analyze the building's health and identify potential structural problems in a timely manner.

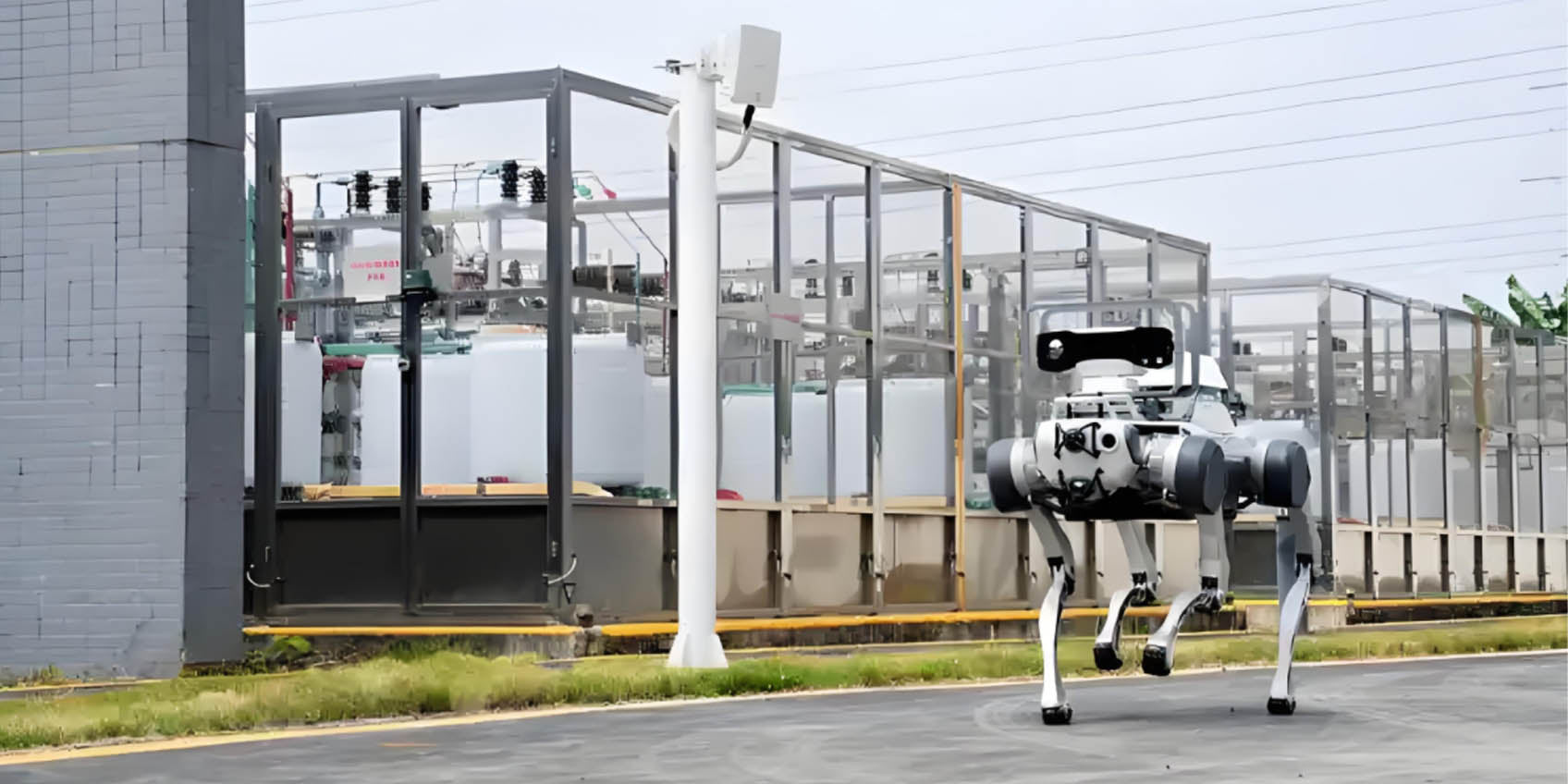

4. Power Facility Inspection

The inspection of power facilities, including substations, power lines, and other essential equipment, is crucial for ensuring the stability of the power system. TOF technology can scan the surface conditions of power facilities, effectively monitoring wear, aging, or potential damage. For instance, during the inspection of high-voltage power lines, TOF sensors can collect fine data from a distance to help inspectors detect potential equipment damage or safety hazards. Using TOF technology for power facility inspections can improve inspection efficiency and avoid the risks associated with high-altitude work, ensuring the stability of the power system.

5. Environmental Monitoring and Disaster Warning

Environmental monitoring is also essential in infrastructure inspection. TOF technology can be combined with environmental sensors to monitor changes in surrounding conditions such as temperature, humidity, and wind speed in real time. By analyzing environmental data alongside the health of infrastructure, potential disaster risks can be detected, such as damage to bridges after floods or earthquakes, or settlement in tunnels following heavy rainfall. The widespread application of TOF technology can provide precise data support for disaster early warning systems, helping relevant authorities prepare preventive measures before crises occur.

Advantages of TOF Technology in Infrastructure Inspection

1. High Precision and Real-time Data

TOF technology can provide millimeter-level measurement precision, accurately detailing infrastructure issues. For example, in bridge monitoring, TOF technology can precisely measure the width and depth of cracks, helping inspectors assess the severity of cracks. Compared to traditional manual inspections, TOF technology provides more intuitive and accurate data, reducing human error and ensuring the reliability of inspection results.

2. Unaffected by Light and Weather Conditions

Traditional inspection methods depend on visual monitoring, which is often affected by weather, lighting, and other environmental factors. TOF technology uses infrared pulses for data collection, meaning it is unaffected by changes in lighting or weather conditions. Whether in bright sunlight, overcast weather, or at night, TOF technology can operate stably. This makes it an ideal choice for round-the-clock, all-weather monitoring.

3. Adaptable to Complex Environments

Infrastructure inspection environments are complex and varied. TOF technology can adapt to different environmental conditions, including large-scale roads, bridges, tunnels, as well as mountainous or underground facilities. TOF sensors can perform high-precision measurements in hard-to-reach areas, providing reliable data support.

4. Cost Savings and Improved Efficiency

With automated inspections, TOF technology significantly reduces the frequency and cost of manual inspections. Inspection personnel can quickly identify problematic areas by analyzing the three-dimensional data provided by TOF technology, reducing unnecessary checks and repetitive tasks. TOF technology also improves data collection speed, allowing inspections to be completed more quickly, thereby enhancing work efficiency.

The Future Trends of TOF Technology in Infrastructure Inspection

With the continuous development of artificial intelligence (AI) and big data technology, TOF technology will be further integrated with these cutting-edge technologies, elevating infrastructure inspections to a higher level of intelligence. By combining AI algorithms and big data analysis, TOF technology can not only monitor infrastructure in real-time but also automate the processing of inspection data, analyze potential risks, and provide early warnings. This will propel infrastructure inspection into a new era of greater intelligence and automation.

Conclusion

The widespread application of TOF technology in infrastructure inspection has not only enhanced inspection efficiency and precision but also ensured stable performance in diverse environments, providing strong support for infrastructure health monitoring. As technology continues to evolve, TOF technology will play an increasingly important role in more fields and industries, pushing infrastructure management toward a smarter, more automated, and more efficient future.

Synexens 3D Of RGBD ToF Depth Sensor_CS30

Our professional technical team specializing in 3D camera ranging is ready to assist you at any time. Whether you encounter any issues with your TOF camera after purchase or need clarification on TOF technology, feel free to contact us anytime. We are committed to providing high-quality technical after-sales service and user experience, ensuring your peace of mind in both shopping and using our products.

-

Posted in

CS30