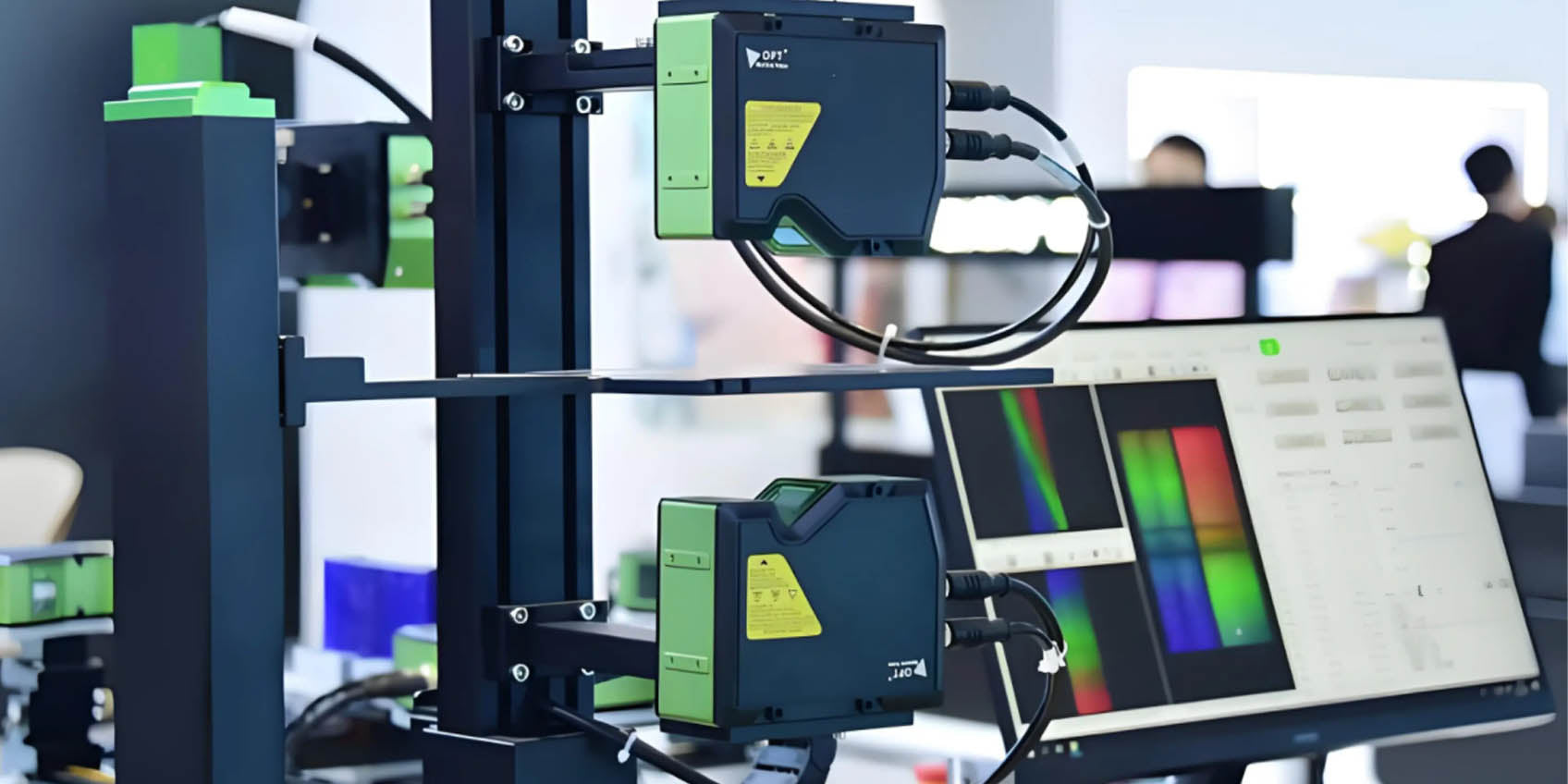

TOF Technology Enhancing 3D Vision Inspection for Quality Control

In modern industrial automation, 3D vision inspection is becoming an important technical support for smart manufacturing. Traditional 2D vision inspection, due to the lack of depth information, often faces limitations such as light, angle, and material factors when recognizing surface defects, measuring dimensions, and aligning positions. TOF (Time of Flight) sensors, as advanced 3D perception technology, measure the flight time of light pulses to obtain high-precision depth information, effectively compensating for the limitations of 2D vision and enabling more accurate quality inspection.

What is a 3D vision inspection?

3D vision inspection is a method that uses three-dimensional imaging technology to detect and analyze objects. By capturing depth information of objects and combining it with 2D image data, it allows for more accurate dimension measurement, defect detection, and position alignment. Compared to traditional 2D vision inspection, 3D vision inspection provides more spatial information, making it suitable for complex shapes, surface defects, and high-precision assembly scenarios. In industrial automation, 3D vision inspection is widely used in product quality control, automated assembly, and robot navigation.

How TOF Technology Improves 3D Vision Inspection Precision

The core advantage of TOF technology lies in its high-precision ranging ability and fast data processing. Traditional 2D vision systems can only capture flat information of objects and cannot accurately judge height, undulations, or depth variations, which is a major limitation in component measurement, welding inspection, complex surface defect identification, and shape matching in manufacturing applications. These limitations affect product quality and production efficiency.

In contrast, TOF sensors emit light pulses and measure their return time to obtain high-precision 3D depth data, enabling precise capture of an object’s shape, contours, and surface details. It can identify minute defects such as surface scratches, material warping, and fine bumps. This information is crucial for high-precision manufacturing.

Moreover, TOF technology has better adaptability to external lighting conditions. Even in high brightness, low light, or uneven lighting environments, it can provide stable and reliable measurement data. Combined with AI algorithms, TOF sensors can intelligently analyze complex structures, enabling automatic sorting, target recognition, and fine assembly, further enhancing the accuracy and reliability of industrial inspection systems to ensure products meet higher quality standards.

TOF Technology Applications in Electronics Manufacturing

In electronics manufacturing, PCB (printed circuit board) soldering quality inspection is a key process. Traditional 2D vision inspection may be prone to misjudgments due to reflection or occlusion when detecting the uniformity of solder joint height and the quality of the weld.

TOF sensors can precisely measure solder joint height and shape, using 3D depth information to determine if there are issues such as cold solder joints, false soldering, or high/low solder points, ensuring that every solder joint meets the standard and avoiding circuit shorts or opens due to solder defects, thus improving the reliability of electronic products.

Additionally, during chip packaging and inspection, TOF technology can be used to measure the thickness of the chips, ensuring that the packaging process meets precision requirements. In high-speed automated production lines, TOF sensors combined with AI vision algorithms can enable rapid online inspection, immediately providing feedback and adjustments when anomalies are detected, avoiding the accumulation of production defects and further improving product yield.

TOF Technology Applications in Automotive Manufacturing

The automotive manufacturing industry requires precise component size measurement and assembly accuracy, as any minor deviation may impact the safety and performance of the vehicle. Traditional measurement methods rely on manual or contact sensors, which are not only inefficient but also difficult to achieve high-precision measurements in complex processes.

TOF technology enables non-contact, high-precision measurement of automotive component sizes, ensuring that each part meets the standard. In body welding, door installation, and glass bonding, TOF sensors can detect height differences at joints, identify welding defects, and ensure assembly consistency and stability.

In automated painting and surface inspection, TOF sensors, combined with 3D vision technology, can precisely measure the coating thickness of vehicle surfaces, identifying issues such as uneven coating or over/thin layers, ensuring that the vehicle’s exterior quality meets industry standards.

TOF Technology Applications in Food Packaging Inspection

The seal integrity of food packaging directly impacts the shelf life and safety of food. Traditional inspection methods often rely on manual sampling or 2D vision systems, which are unable to comprehensively detect issues such as leakage, damage, or deformation of the packaging.

TOF sensors can highly precisely 3D scan food packaging bags, bottle caps, and sealed boxes, identifying any minor deformation or sealing issues. On food production lines, TOF technology can enable non-contact online inspection, combined with AI algorithms, to automatically remove defective products, ensuring that food meets quality standards before entering the market.

TOF Technology Promoting Smart Manufacturing Development

With the advancement of Industry 4.0, the production process is moving toward intelligent, high-precision, and unmanned directions. TOF technology, as an efficient 3D vision inspection solution, makes industrial quality control more precise and efficient.

In the future, as the resolution of TOF sensors improves, computational power increases, and AI deep learning is integrated, TOF technology will play a role in more fields, including smart warehousing, robot vision, logistics sorting, and more, further promoting the development of industrial automation and improving the competitiveness of manufacturing industries.

Conclusion

With its high-precision ranging, fast response, and adaptability to complex lighting environments, TOF technology is becoming an essential technology for 3D vision inspection and quality control. Industries such as electronics manufacturing, automotive production, and food packaging are rapidly adopting TOF technology to improve inspection accuracy and reduce defect rates. As smart manufacturing continues to upgrade, TOF technology will play an even more crucial role in the future of industrial automation.

Synexens Industrial Outdoor 4m TOF Sensor Depth 3D Camera Rangefinder_CS40p

After-sales Support:

Our professional technical team specializing in 3D camera ranging is ready to assist you at any time. Whether you encounter any issues with your TOF camera after purchase or need clarification on TOF technology, feel free to contact us anytime. We are committed to providing high-quality technical after-sales service and user experience, ensuring your peace of mind in both shopping and using our products.

-

Posted in

CS40P