TOF Cameras in Industrial Robots : From Positioning to Avoidance

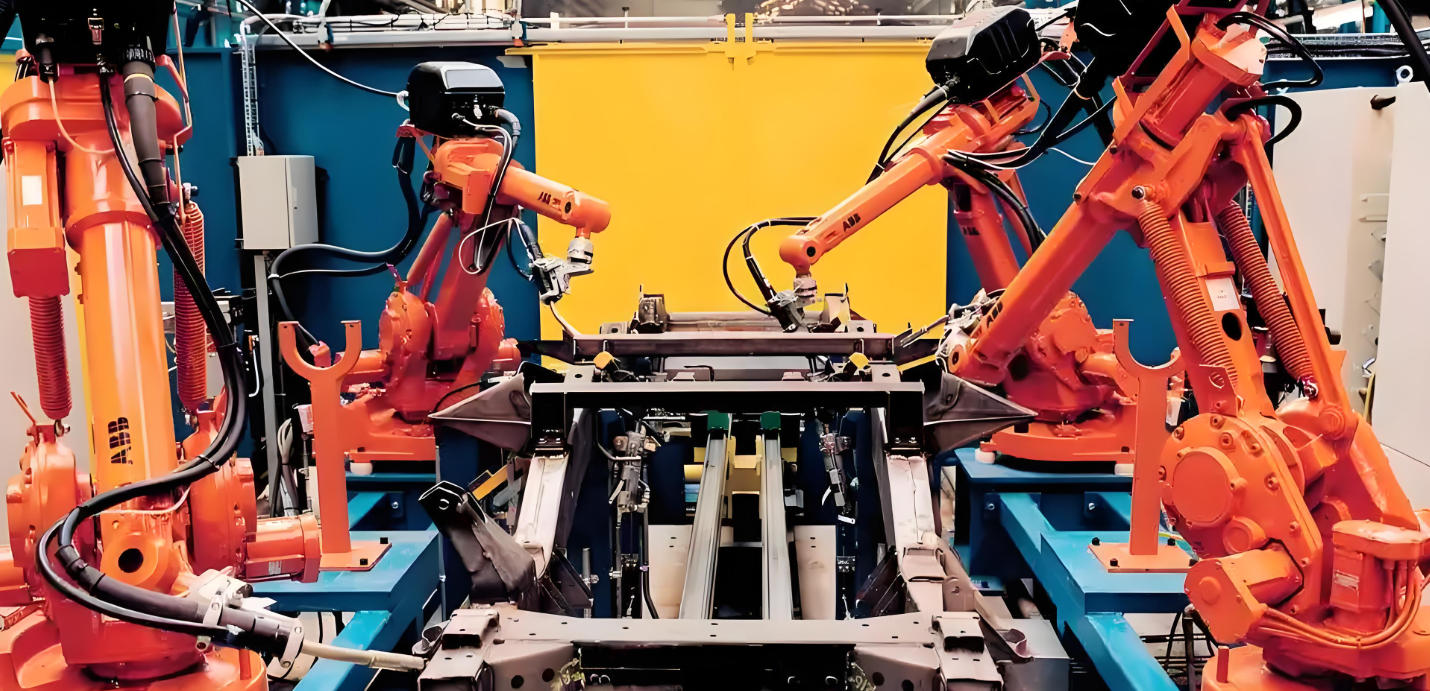

Amid the wave of smart manufacturing and Industry 4.0, industrial robots are evolving from traditional automation to high-precision, intelligent operations. To achieve efficient picking, precise positioning, and safe obstacle avoidance, TOF (Time-of-Flight) cameras have become a key technology. With real-time 3D spatial sensing capabilities, TOF enables robots to operate stably in complex production environments, enhancing efficiency and safety, and laying the foundation for a comprehensive upgrade of smart factories.

What is a depth camera?

A depth camera is a type of camera that can capture not only 2D images but also the distance (depth) information of objects in a scene. Unlike traditional cameras that only record color and brightness, a depth camera measures how far each point in the image is from the sensor, producing a 3D map of the environment.

There are different technologies used in depth cameras, including:

-

Time-of-Flight (TOF): Emits light pulses and calculates distance based on the time it takes for the light to return.

-

Structured Light: Projects a pattern onto objects and measures how the pattern deforms to calculate depth.

-

Stereo Vision: Uses two cameras to simulate human binocular vision and estimate depth from disparities between images.

Applications of depth cameras include:

-

AR/VR (Augmented and Virtual Reality): Building immersive 3D environments.

-

Robotics: Enabling navigation, object recognition, and obstacle avoidance.

-

Smartphones & Wearables: Facial recognition, gesture control, and 3D scanning.

-

Industrial Use: Quality inspection, automation, and safety monitoring.

Depth camera is essential for any system that needs to understand the world in three dimensions.

How are TOF depth cameras applied in industrial robots, and what advantages do they bring for positioning and obstacle avoidance?

TOF depth cameras have become a key component in industrial robotics, providing real-time 3D depth camera perception. Unlike traditional 2D vision systems, a camera for 3D sensing can capture not only shape but also distance, enabling robots to understand their surroundings with high precision.

Through a camera depth sensor keying process, TOF systems generate accurate depth maps, allowing robots to identify objects, measure distances, and perform safe navigation. The field of view of a camera (also referred to as camera FOV or camera field of view) determines how much of the environment the robot can see, which is crucial for tasks such as automated assembly, logistics, and warehouse operations.

By integrating camera depth data with motion algorithms, TOF-based robots gain the ability to position themselves accurately, detect obstacles, and avoid collisions. This upgrade from simple navigation to intelligent spatial awareness makes TOF 3D depth cameras a cornerstone technology for the next generation of industrial automation.