How TOF Technology Enhances Safety Monitoring and Reduces Risk

In modern industrial production, safety is always the top priority. With the increasing complexity of production environments and the rise of automation, traditional safety monitoring systems have gradually exposed their limitations. For example, traditional methods relying on cameras and infrared sensors are limited by lighting, environmental interference, and changing conditions, making it difficult to provide accurate safety guarantees. The introduction of TOF (Time of Flight) technology, with its precise 3D depth perception capability, allows for efficient and stable performance in harsh environments, improving safety and protective capabilities during production processes.

How TOF Technology Improves Industrial Safety Monitoring

The main advantage of TOF technology lies in its precise three-dimensional spatial awareness. Unlike traditional two-dimensional sensors, TOF sensors measure the time it takes for light pulses to return to precisely obtain the three-dimensional depth information of objects, ensuring stable performance in complex environments. Traditional safety monitoring devices such as cameras and infrared sensors are often limited by environmental factors like strong light, dust, and smoke, but TOF technology is unaffected by these factors, providing more accurate safety data.

No Lighting Interference

TOF sensors do not rely on ambient light to gather data. The principle is to emit light pulses and measure the time it takes for the light waves to return to calculate the distance. As a result, it is not affected by strong lighting, shadows, or other factors. In complex or extreme lighting conditions such as mining areas, smelting plants, and chemical factories, traditional cameras and infrared sensors struggle to perform, but TOF sensors can accurately capture the three-dimensional position of objects, ensuring the accuracy and reliability of monitoring data.

High-Precision Distance Measurement

TOF technology’s high-precision distance measurement capabilities allow it to provide very accurate three-dimensional data in various industrial applications. Whether in high-temperature, high-pressure, or low-temperature environments, TOF sensors can offer millimeter- or even micrometer-level accuracy, helping systems precisely perceive the boundaries of hazardous areas or detect worker positions. This precision is particularly useful in high-risk operations like heavy machinery operation or automated assembly lines, providing robust protection for industrial safety.

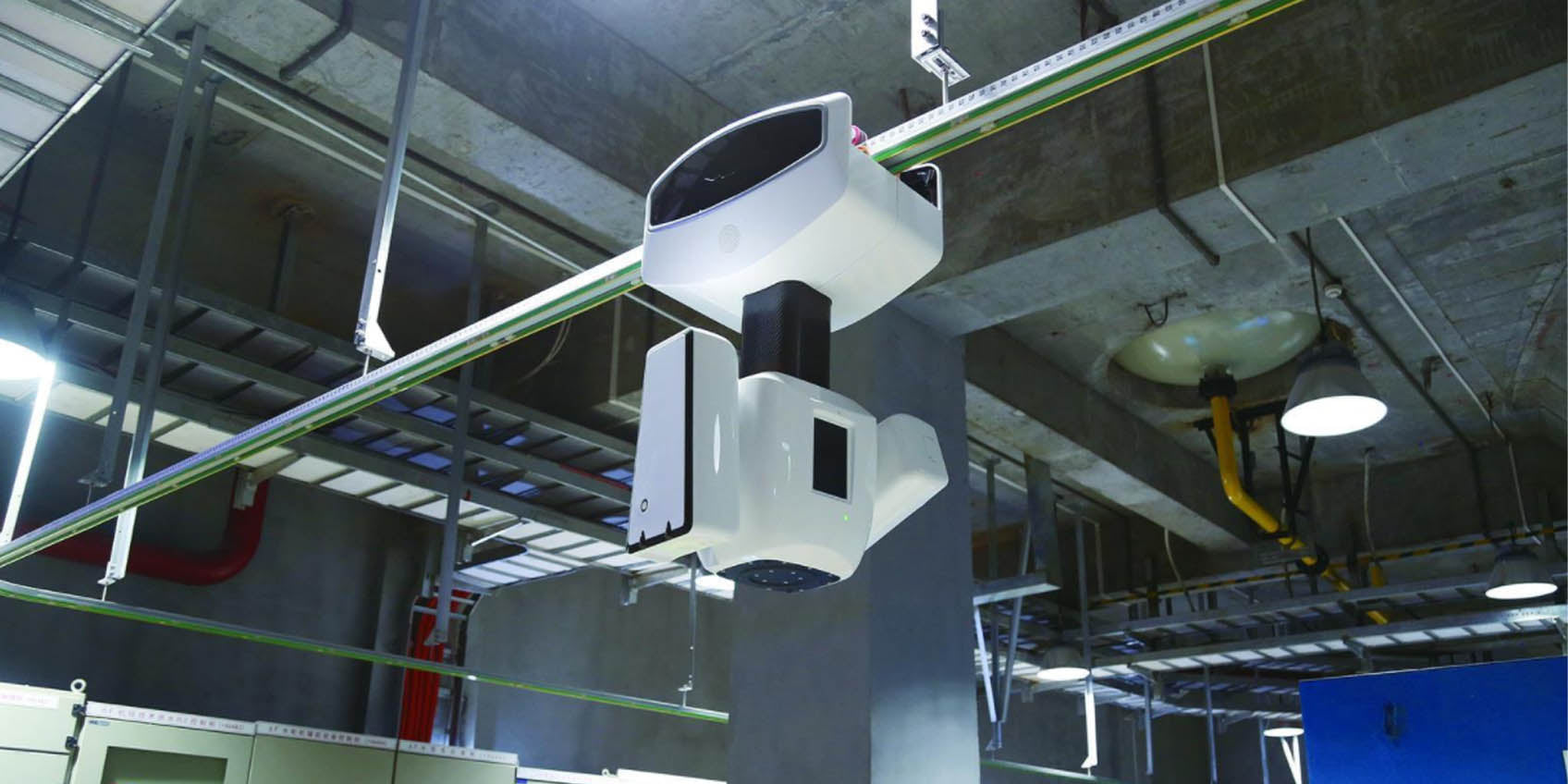

TOF Technology in Safety Fencing Applications

In high-risk environments, the establishment of virtual safety fences is an effective means of ensuring safe production. By installing TOF sensors, virtual fences can be set up around production areas. When workers or equipment enter dangerous zones, the system will automatically trigger alarms or take safety measures to prevent accidents. TOF technology not only monitors the dynamics of personnel or equipment in real time but also provides more accurate location information through 3D data, enabling proactive responses.

For example, in chemical plants and smelting industries, where the work environment is complex and hazardous, traditional safety fences may fail due to environmental factors, while TOF technology can operate stably in such environments to ensure workers stay out of dangerous areas. This virtual safety fence helps create a smarter production environment, dynamically adjusting and responding to potential safety hazards.

TOF Technology Linked to Automated Safety Systems

The introduction of TOF technology not only improves the accuracy of safety monitoring systems but also enables integration with other automated equipment and systems to create intelligent safety protection. For example, by combining temperature sensors, gas leak detectors, and other sensors, TOF technology can comprehensively assess the status of hazardous areas, enabling multi-level, multi-angle safety monitoring.

In heavy machinery work zones, TOF technology can capture the 3D position and motion trajectories of robotic arms, conveyor belts, and other equipment in real time, quickly determining if there are safety risks and preventing accidents caused by abnormal equipment. By linking with other sensors, the TOF system can identify potential hazards between personnel and equipment in advance and automatically activate safety measures to reduce the likelihood of accidents.

Enhancing Environmental Monitoring in Industrial Environments

TOF technology is not only used for personnel safety monitoring but also greatly enhances environmental monitoring capabilities across industrial environments. In dangerous environments like high temperatures, high pressure, smoke, and flames, TOF sensors can accurately detect environmental changes and provide necessary real-time feedback for safety monitoring systems. When the system detects an anomaly, it can quickly respond to avoid accidents like fires or explosions.

For instance, in the pharmaceutical and food processing industries, where clean room environments are critical, even the slightest movement or environmental change can affect product quality. TOF sensors can monitor the movement of objects in clean rooms in real time, ensuring the stability of the dust-free environment and preventing contamination or production anomalies.

Examples in High-Risk Industries

-

Chemical Industry: In chemical plants, various dangers such as toxic gas leaks and high-temperature operations exist. TOF technology can monitor whether personnel enter dangerous areas, preventing exposure to hazardous environments. Combined with gas leak detectors, TOF sensors can help pinpoint leak sources and avoid accidents.

-

Smelting Industry: In smelting operations, high temperatures, dust, and hazardous working conditions are common. TOF technology can detect the real-time location of workers, issue timely alerts, and ensure workers stay away from high-temperature, high-pressure equipment, reducing injuries.

-

Mining Industry: In mining operations, the work environment is complex and dangerous. TOF sensors can monitor workers' 3D positions in real time and ensure they don’t enter hazardous areas by creating virtual safety fences. The system can also detect environmental changes and issue real-time warnings to prevent mining accidents.

Conclusion

TOF technology, with its high-precision distance measurement, independence from lighting interference, and real-time responsiveness, is becoming a key technology for industrial safety monitoring. By integrating with other automation systems, TOF technology ensures personnel safety and enhances the overall safety of the production environment. As industrialization continues to rise, the application of TOF technology will expand, playing a greater role in high-risk industries, and becoming a solid safeguard for industrial safety.

Synexens Industrial Outdoor 4m TOF Sensor Depth 3D Camera Rangefinder_CS40p

After-sales Support:

Our professional technical team specializing in 3D camera ranging is ready to assist you at any time. Whether you encounter any issues with your TOF camera after purchase or need clarification on TOF technology, feel free to contact us anytime. We are committed to providing high-quality technical after-sales service and user experience, ensuring your peace of mind in both shopping and using our products.

-

Posted in

CS40P